West of Roseville, Ill. in the land of corn and soybeans stands a self-made business. While many locals are not sure what goes on there, numerous worldwide businesses do.

Fresh out of high school, Brandon Bentz took off for the University of South Dakota to study criminal justice. He lasted less than a semester, left school and started working for a mechanical millwright.

“Taking chances, hard work, utilizing your resources, listening to your gut and a bit of luck can propel you to do things outside of the norm that society says you cannot succeed in,” Brandon says. “I think the point here is that school is not for everyone, but that does not mean your opportunities are gone.”

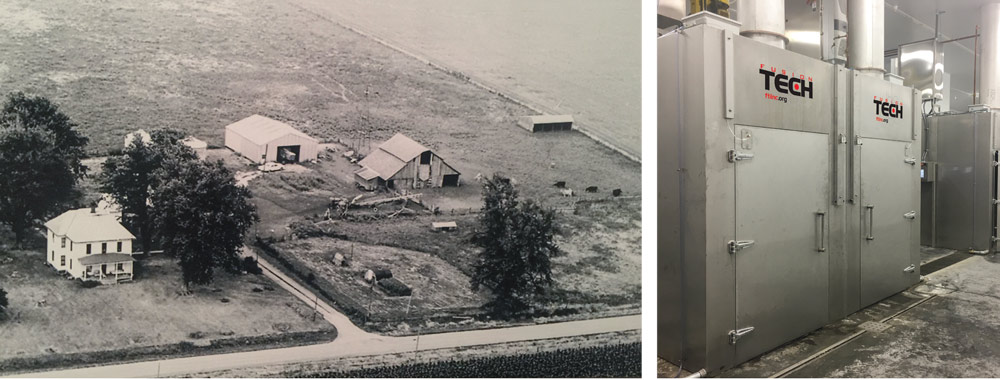

In 1998, Fusion Tech Integrated was born. Brandon began a small fabrication shop in his two-car garage in the middle of nowhere in Warren County. He hired two individuals from the local community; one who still works there today.

Brandon’s interest in the fabrication business was piqued at a young age. “My dad owned a blacksmith shop in western Iowa. My brother and I have been around this type of work since we were young,” he explains.

Owners and husband-wife duo, Brandon and Kathy Bentz, have now been in the business for two decades. Brandon tends to focus on the design and manufacturing side of the business, which is his strength, while Kathy manages the financial side.

What began with only three employees has grown into a nation-wide company with international reach, employing nearly 100 dedicated people across manufacturing, drafting and design, project management, customer service, and sales and marketing. Many who have been there for a long time.

After a year in the garage, they officially decided they needed a bigger space because Fusion Tech was providing a service most fabrication shops didn’t: custom parts and equipment. They broke ground on the same land as the original two-car garage and built their first manufacturing facility – referred to as Shop 1 and then later, shops 2 and 3.

“We were doing a project for Global Foods in Sioux City, Iowa, and we were building conveyance lines in sections and assembling them outside in the gravel driveway. We would use a tractor with a loader bucket, that I had to borrow, and we would drag and lift each section out of the garage and set it up outside,” Brandon explains. “To say the least, it wasn’t efficient and was really difficult to tell your customer that his equipment was being built outside.”

Today, the Roseville location encompasses over 50,000 square feet of manufacturing floor space, and the original two-car garage is now the drafting and design office. Most recently, Fusion Tech acquired the homestead on the land. It will utilize that space to expand and provide more office space for employees in addition to a large conference room to be used for meetings and customer training events.

Dedication to quality and drive for innovation keeps Fusion Tech on the leading edge.

“We never expected our business, based out of a garage in the rural part of west-central Illinois to become a brand name known and preferred by some of the biggest names in the food processing industry,” Brandon says. “But that’s what we did.”

Kathy adds, “We started on my family’s farm. I’m of the opinion that we’ve been able to grow as successfully as we have because of the great examples we’ve had in front of us.”

Not only have they expanded on their original footprint, there is also an offsite drafting office located in Dakota Dunes, S.D.

Fusion Tech manufactures a wide range of custom designed solutions for the food processing industry — from conveyors, dumpers, hoppers, slicers, shredders, ovens, custom designed equipment and tanks to platforms, ergonomic stands, drains, bollards, carts, racks, wash stations, and more. Its “small” size allows the company to adapt and grow quickly – eliminating the need for multiple vendors and simplifying the process for their customers.

They are experts at taking those “napkin sketch” notes and drawings and turning them into solutions for food processing facilities across the country for some of the largest food processing companies in the industry, including Smithfield Foods, American Foods Group, Hormel Foods, Cargill Meat Solutions, SugarCreek, Creekstone Farms, Premium Pet Health, Boar’s Head, Beef Products, Wells Enterprises/Blue Bunny, Tyson, John Morrell, Farmland, Pinnacle Foods Corporation, Schwan’s, Nestle and many more.

The latter part of 2015, Fusion Tech officially launched into the thermal processing industry with the acquisition of Cove Equipment. After some redevelopment of its technology and designs, it quickly became a big competitor in the market, winning jobs over companies three to four times its size that has been developing smokehouses and dehydrators for decades.

As a locally-grown company, Fusion Tech is invested in the community. It has an ongoing commitment to the economic growth and stability of the region – hiring from the local workforce during expansions, sourcing materials and supplies from local businesses, and giving back to support its schools, city and county festivals, local veterans and so much more.

The business has grown leaps and bounds over the past two decades, so what’s next? “We’re looking to invest in a new research and development facility in the area to develop new equipment, provide testing of our standard equipment, train employees and customers, as well as help companies launch new food products,” Brandon explains.

The Bentz’s 16-year-old son is working at Fusion Tech for the summer. Brandon says it’s too early to tell if their children will someday have an interest in the business. He states, “I do not pressure my kids into wanting to be a part of the business in the future. This type of work may not be for them, and we are fine with that.”

Regardless if the Bentz kids want to continue on in the family business, Fusion Tech and its local roots is a company that will continue to be a big player in the industry for years to come.

For more details about Fusion Tech Integrated, visit ftiinc.org.